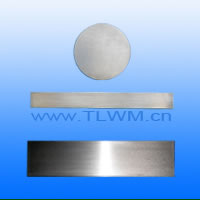

Molybdenum Sheet

Description:

Chemical cleaned molybdenum sheets are with metallic silver luster. They're .rolled and annealed to reach the optimum condition for the desired end use. We can provide molybdenum sheets with different widths, thicknesses, surface conditions as well as impurity conditions upon the customers' requirements.

Features:

1. The purity of pure molybdenum sheet is over 99.95%. While the purity of high-temperature rare-earth element added molybdenum sheet is above 99%;

2. The density of molybdenum sheet is more than or equals to 10.1g/cm3;

3. The flatness is less than 3%;

4. It has good performances of high strength, uniform internal organization and good resistance to high temperature creep;

Application:

1. Molybdenum sheets are used for producing heat shields, covers, heating belts and connecting parts in sapphire growth furnace or vacuum furnace;

2. They also can be applied in sputtering targets for plasma coating, high temperature resistant boat, etc;

3. They are also adopted as materials for manufacuturing illumination parts, high temperature shields, sintering boats as well as high temperature vessels;

4. Molybdenum sheets can be used for heating elements, electronic vacuum furnaces and semiconductors.

Productive Technology:

1. Production Process: Molybdenum Billet (Raw Materials) - Examine - Hot Rolling - Leveling and Annealing - Caustic Wash - Reexamine – Moderate Temperature Rolling - Vacuum Annealing – Third Examine - Cold Rolling - Leveling – Shearing and Vacuum Annealing – Final Examine- Packaging;

2. Technical Essentials: Selecting superior quality of raw material, LTWM adopts normative operating instruction and reasonable production process. What's more, our company introduces advanced grinding machine with double faces and four directions to output molybdenum sheets with clean and smooth surfaces. The quality and accuracy of sheet surfaces can reach the world's advanced level.

Packing and Shipping:

We deliver molybdenum sheets in plywood cases by ocean shipping or air transportation.

- TZM AlloysTZM alloy is a high strength molybdenum based alloy containing titanium, zirconium and carbon. Comparing to pure molybdenum products, it has better creep resistance, higher recrystallization temperature and better welding properties. Concerning the tensile strength at 1100℃, TZM alloy is about twice as ...