TZC Alloys

Description:

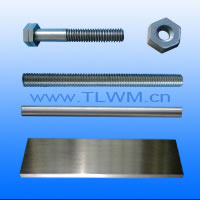

TZC alloy is one of main classes of commercial molybdenum-base alloys. It contains molybdenum mainly as well as 1.2% titanium, 0.3% zirconium and 0.1% carbon. TZC alloy is an improvement of TZM alloy. By using powder metallurgy and vacuum melting method, LTWM provides superior TZC alloys with excellent performance according to the customer drawings.

Features:

1. TZC alloy has excellent high temperature strength and high recrystallization temperature above 1300℃;

2. TZC alloy has higher creep strength and higher tensile strength than pure molybdenum products;

3. It also has good plasticity at room temperature;

Application:

1. TZC alloy can be used as high temperature structural materials and high temperature processing tool materials in very bad conditions;

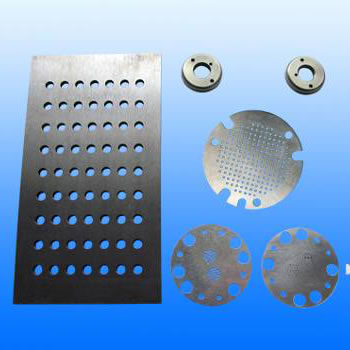

2. It can be used for manufacturing aluminum and copper alloys, cast iron and iron-based alloy as well as die-casting molds;

3. It can be used for producing cores of stainless steel, such as hot extrusion tools, seamless steel pipe, thermal processing head, etc;

4. TZC also can be adopted for making space rockets flying devices and their surface components;

Parameters of TZC Alloy:

LTWM could offer all kinds of TZC alloys in rods, plates and fabricated parts on request.

Packing and Shipping:

We deliver TZC alloys in plywood cases by ocean shipping or air transportation.

- Molybdenum Parts for Industrial FurnaceLTWM provides molybdenum parts for industrial furnace with superior quality, high accuracy, excellent machinability as well as moderate price. All our molybdenum parts possess good properties of high purity, high density, high temperature resistance as well as stable internal structure. We adopt advanced techniques and ...