Introduction about Sputtering and Sputtering Processes:

Sputtering is a physical vapor deposition (PVD) method of depositing the evaporated target material onto the surface of the substrate to form a thin film layer. It is the preferred vacuum deposition technique adopted by manufacturers of semiconductors, CDs, disk drives, and optical devices. It is extensively used in the semiconductor industry to deposit thin films of various materials in integrated circuit processing. Thin anti-reflection coatings on glass for optical applications are also deposited by sputtering. Sputtered films possess excellent uniformity, density, purity and adhesion.

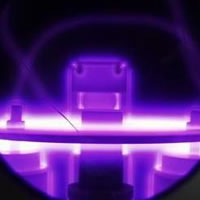

Sputtering processes can be classified into several types, including ion beam, diode and magnetron sputtering. In the sputtering process, substrates are placed into the vacuum chamber and are pumped down to their process pressure. When a negative charge is applied to the target material (material to be deposited), sputtering starts and causes a plasma or glow discharge. While positive charged gas ions generated in the plasma region are attracted to the negative biased target plate at a very high speed. This collision creates a momentum transfer and ejects atomic size particles from the target. These particles traverse the chamber and are deposited as a thin film onto the surface of the substrates.

Tungsten and Molybdenum Sputtering Targets:

Adopting above 99.95% super purity tungsten or molybdenum, LTWM professionally provide all kinds of tungsten and molybdenum sputtering targets with high density, high precision, homogeneous structure and good thermal conductivity for customers. We ensure our sputtering targets are of high efficiency and high utilization rate.

Tungsten and molybdenum sputtering targets are mainly used in fields of aerospace, rare-earth smelting, electric light, chemical equipment, medical equipment, metallurgical machinery, smelting equipment, petroleum and many others. Specific speaking, they can be used for producing panel display, architectural glass, automotive glass, optical film glass, solar cell, recording media, microelectronics, automotive light and decorative coating, etc. LTWM could provide tungsten and molybdenum sputtering targets in shapes of plate, tube, bar, block, rod, square, column or according to customer drawing. We deliver tungsten and molybdenum sputtering targets in plywood cases by ocean shipping or air transportation.